Optical alignment is a critical process in various fields, including physics, engineering, and optics. It involves positioning optical components, such as lenses, mirrors, and beam splitters, to achieve precise alignment and maximize the performance of an optical system. In this article, we will provide 5 opto alignment tips to help you achieve accurate and efficient alignment of your optical components.

Key Points

- Understand the optical system and its components to determine the optimal alignment strategy

- Use high-quality optical components and mounting hardware to minimize errors and ensure stability

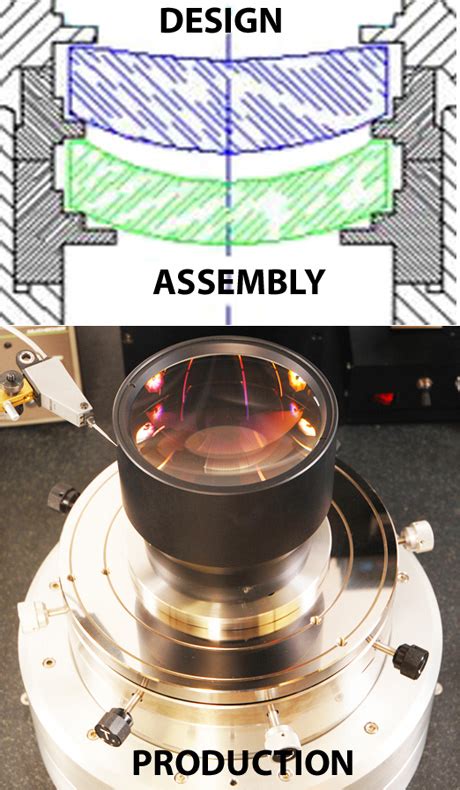

- Employ a combination of optical and mechanical alignment techniques to achieve precise alignment

- Utilize alignment tools and software to streamline the alignment process and reduce errors

- Verify and validate the alignment using various testing and measurement techniques

Understanding the Optical System

To achieve accurate opto alignment, it is essential to have a thorough understanding of the optical system and its components. This includes knowledge of the optical components, such as lenses, mirrors, and beam splitters, as well as the mounting hardware and any other supporting structures. By understanding how these components interact and affect the overall performance of the system, you can determine the optimal alignment strategy and make any necessary adjustments.

For example, in a beam splitter-based optical system, the alignment of the beam splitter is critical to achieving the desired splitting ratio and minimizing losses. By understanding the optical properties of the beam splitter and how it interacts with the other components, you can develop an effective alignment strategy that ensures optimal performance.

High-Quality Optical Components and Mounting Hardware

Using high-quality optical components and mounting hardware is crucial for achieving accurate opto alignment. High-quality components are designed to minimize errors and ensure stability, which is essential for maintaining precise alignment over time. Additionally, using high-quality mounting hardware, such as kinematic mounts and adjustment screws, can provide the necessary flexibility and precision to achieve optimal alignment.

For instance, using a high-quality lens with a precise focal length and minimal aberrations can help to minimize errors and ensure that the optical system performs as expected. Similarly, using a kinematic mount with precise adjustment screws can provide the necessary flexibility to achieve optimal alignment of the lens and other components.

| Optical Component | Alignment Requirement |

|---|---|

| Beam Splitter | Precision alignment to achieve desired splitting ratio |

| Lens | Precision alignment to minimize aberrations and ensure optimal focus |

| Mirror | Precision alignment to minimize losses and ensure optimal reflectivity |

Optical and Mechanical Alignment Techniques

A combination of optical and mechanical alignment techniques is often necessary to achieve precise opto alignment. Optical alignment techniques, such as using laser beams or optical fibers, can provide precise alignment of the optical components, while mechanical alignment techniques, such as using adjustment screws and kinematic mounts, can provide the necessary flexibility and precision to achieve optimal alignment.

For example, using a laser beam to align a lens can provide precise alignment of the lens and minimize aberrations. Additionally, using a kinematic mount with adjustment screws can provide the necessary flexibility to achieve optimal alignment of the lens and other components.

Alignment Tools and Software

Alignment tools and software can be used to streamline the opto alignment process and reduce errors. These tools can provide precise alignment of the optical components and help to minimize losses and aberrations. Additionally, alignment software can be used to simulate the optical system and predict the effects of different alignment strategies, which can help to optimize the alignment process.

For instance, using alignment software to simulate the optical system can help to predict the effects of different alignment strategies and optimize the alignment process. Additionally, using alignment tools, such as laser beams or optical fibers, can provide precise alignment of the optical components and help to minimize losses and aberrations.

Verification and Validation

Verifying and validating the opto alignment is critical to ensuring that the optical system performs as expected. This can be done using various testing and measurement techniques, such as interferometry or spectroscopy, to verify the alignment of the optical components and ensure that the system is performing optimally.

For example, using interferometry to verify the alignment of a lens can provide precise measurement of the lens’s optical properties and ensure that it is aligned correctly. Additionally, using spectroscopy to measure the spectral properties of the optical system can help to verify that the system is performing as expected and that the alignment is optimal.

What is the most important factor in achieving accurate opto alignment?

+The most important factor in achieving accurate opto alignment is a thorough understanding of the optical system and its components. This includes knowledge of the optical components, such as lenses, mirrors, and beam splitters, as well as the mounting hardware and any other supporting structures.

How can I verify the alignment of my optical system?

+Verifying the alignment of your optical system can be done using various testing and measurement techniques, such as interferometry or spectroscopy. These techniques can provide precise measurement of the optical properties of the system and ensure that it is aligned correctly.

What are the benefits of using high-quality optical components and mounting hardware?

+The benefits of using high-quality optical components and mounting hardware include minimizing errors and ensuring stability, which is essential for maintaining precise alignment over time. Additionally, using high-quality components can help to ensure that the optical system performs as expected and that the alignment is optimal.

In conclusion, achieving accurate opto alignment requires a thorough understanding of the optical system and its components, as well as the use of high-quality optical components and mounting hardware. By employing a combination of optical and mechanical alignment techniques, utilizing alignment tools and software, and verifying and validating the alignment, you can ensure that your optical system performs optimally and maintains precise alignment over time.