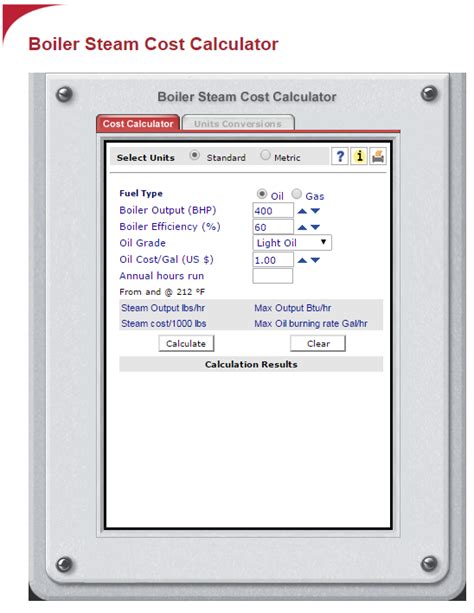

The Steam Cost Calculator is a vital tool for industries that rely heavily on steam power, such as manufacturing, chemical processing, and power generation. Steam costs can significantly impact a company's bottom line, and accurately calculating these costs is essential for making informed decisions about energy management and process optimization. In this article, we will delve into the world of steam cost calculation, exploring the key factors that influence steam costs, the different methods of calculation, and the benefits of using a steam cost calculator.

Key Points

- Understanding the factors that affect steam costs, such as fuel prices, boiler efficiency, and steam pressure, is crucial for accurate calculation.

- There are different methods of calculating steam costs, including the fuel-based method, the heat-based method, and the steam generator-based method.

- A steam cost calculator can help industries optimize their steam usage, reduce energy costs, and improve overall efficiency.

- Regular maintenance and monitoring of steam systems can help identify areas for improvement and reduce steam costs.

- Implementing energy-efficient technologies, such as condensate recovery systems and steam traps, can significantly reduce steam costs.

Factors Affecting Steam Costs

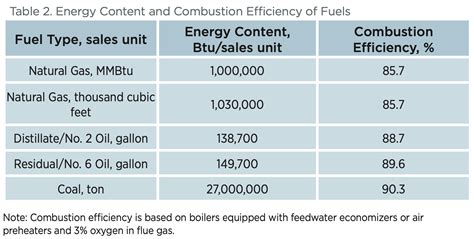

Steam costs are influenced by a variety of factors, including fuel prices, boiler efficiency, steam pressure, and condensate return. Fuel prices, in particular, can have a significant impact on steam costs, as they can account for up to 80% of the total cost. Boiler efficiency is also a critical factor, as it determines how much energy is required to produce a given amount of steam. Steam pressure, too, plays a role in steam costs, as higher pressures require more energy to achieve. Finally, condensate return is essential for reducing steam costs, as it allows for the recovery of heat energy that would otherwise be lost.

Fuel-Based Method of Steam Cost Calculation

The fuel-based method of steam cost calculation involves determining the cost of fuel required to produce a given amount of steam. This method takes into account the fuel price, boiler efficiency, and steam pressure. The formula for calculating steam costs using the fuel-based method is as follows: Steam Cost = (Fuel Price x Fuel Consumption) / (Boiler Efficiency x Steam Pressure). For example, if the fuel price is 10 per million Btu, the fuel consumption is 100 million Btu per hour, the boiler efficiency is 80%, and the steam pressure is 100 psig, the steam cost would be 12.50 per 1,000 pounds of steam.

| Factor | Value |

|---|---|

| Fuel Price | $10 per million Btu |

| Fuel Consumption | 100 million Btu per hour |

| Boiler Efficiency | 80% |

| Steam Pressure | 100 psig |

| Steam Cost | $12.50 per 1,000 pounds of steam |

Benefits of Using a Steam Cost Calculator

A steam cost calculator can help industries optimize their steam usage, reduce energy costs, and improve overall efficiency. By providing a detailed breakdown of steam costs, a steam cost calculator can help identify areas for improvement and provide a basis for making informed decisions about energy management and process optimization. Additionally, a steam cost calculator can help industries compare the costs of different fuels and determine the most cost-effective option.

Steam Generator-Based Method of Steam Cost Calculation

The steam generator-based method of steam cost calculation involves determining the cost of steam produced by a steam generator. This method takes into account the cost of fuel, the efficiency of the steam generator, and the amount of steam produced. The formula for calculating steam costs using the steam generator-based method is as follows: Steam Cost = (Fuel Cost x Fuel Consumption) / (Steam Generator Efficiency x Steam Production). For example, if the fuel cost is 10 per million Btu, the fuel consumption is 100 million Btu per hour, the steam generator efficiency is 80%, and the steam production is 10,000 pounds per hour, the steam cost would be 12.50 per 1,000 pounds of steam.

In conclusion, calculating steam costs is a complex process that requires careful consideration of various factors, including fuel prices, boiler efficiency, steam pressure, and condensate return. By using a steam cost calculator and understanding the different methods of calculation, industries can optimize their steam usage, reduce energy costs, and improve overall efficiency.

What is the most significant factor affecting steam costs?

+Fuel prices are the most significant factor affecting steam costs, as they can account for up to 80% of the total cost.

How can industries optimize their steam usage and reduce energy costs?

+Industries can optimize their steam usage and reduce energy costs by using a steam cost calculator, implementing energy-efficient technologies, and regularly maintaining and monitoring their steam systems.

What is the benefit of using a steam cost calculator?

+A steam cost calculator can help industries identify areas for improvement, compare the costs of different fuels, and make informed decisions about energy management and process optimization.