The world of supply chain management is an intricate and dynamic field, playing a pivotal role in shaping the success and sustainability of businesses across industries. As the global marketplace continues to evolve, understanding and implementing effective supply chain practices have become essential for companies to stay competitive, efficient, and responsive to market demands.

This article aims to delve into the core aspects of supply chain practices, exploring the strategies, technologies, and innovations that are shaping the industry. By examining real-world examples, industry trends, and expert insights, we will provide a comprehensive guide to navigating the complexities of modern supply chain management.

Optimizing Supply Chain Networks

Efficient supply chain networks are the backbone of any successful business, ensuring the seamless flow of goods and services from origin to end-user. To optimize these networks, companies employ a range of strategies, including:

Network Design and Planning

The design of a supply chain network is critical to its overall performance. Factors such as facility location, transportation routes, and inventory management strategies are carefully considered to minimize costs, maximize efficiency, and ensure timely delivery.

For instance, consider the case of Company X, a global manufacturer of electronic components. By analyzing market demand, transportation costs, and lead times, Company X optimized its network design, reducing overall transportation costs by 15% and improving on-time delivery by 20%.

Collaborative Planning and Forecasting

Collaborative planning and forecasting involve bringing together various stakeholders, including suppliers, manufacturers, and distributors, to align their efforts and improve overall supply chain performance. By sharing data and insights, companies can better anticipate demand fluctuations, optimize inventory levels, and improve overall supply chain resilience.

A real-world example of collaborative planning can be seen in the automotive industry, where OEMs (Original Equipment Manufacturers) work closely with their suppliers to forecast demand and optimize production schedules. This collaborative approach has led to significant improvements in inventory management and reduced lead times, enhancing overall supply chain efficiency.

Leveraging Technology for Supply Chain Excellence

In today’s digital age, technology plays a pivotal role in enhancing supply chain operations. Here are some key technological advancements and their impact on supply chain practices:

Artificial Intelligence and Machine Learning

AI and ML algorithms are revolutionizing supply chain management by enabling predictive analytics, demand forecasting, and optimization of inventory levels. These technologies can analyze vast amounts of data, identify patterns, and make accurate predictions, helping companies make informed decisions and improve overall supply chain performance.

For example, Retailer Y, a leading online retailer, leverages AI-powered demand forecasting to optimize its inventory management. By analyzing historical sales data, market trends, and customer behavior, Retailer Y has reduced its stock-out rates by 30% and improved its overall customer satisfaction.

Internet of Things (IoT) and Real-Time Tracking

The IoT has transformed supply chain visibility by enabling real-time tracking of goods and assets. With IoT-enabled sensors and devices, companies can monitor the location, condition, and status of their shipments, ensuring timely deliveries and minimizing the risk of loss or damage.

Consider the logistics industry, where Logistics Provider Z has implemented IoT-based tracking solutions. By integrating GPS tracking and temperature sensors, Logistics Provider Z can provide real-time visibility to its clients, ensuring timely deliveries and maintaining the integrity of temperature-sensitive goods.

Sustainable Supply Chain Practices

As environmental and social sustainability become increasingly important, companies are adopting sustainable practices throughout their supply chains. Here are some key strategies for achieving a more sustainable supply chain:

Reducing Carbon Footprint

Companies are implementing various initiatives to reduce their carbon emissions throughout the supply chain. This includes optimizing transportation routes, investing in energy-efficient technologies, and adopting renewable energy sources.

A notable example is Manufacturer A, which has committed to a net-zero carbon emissions target by 2030. To achieve this goal, Manufacturer A has implemented a range of initiatives, including transitioning to electric delivery vehicles, optimizing transportation routes to reduce mileage, and investing in renewable energy sources for its facilities.

Ethical Sourcing and Supplier Responsibility

Ensuring ethical sourcing practices and maintaining responsible supplier relationships are essential aspects of sustainable supply chain management. Companies are now evaluating suppliers based on their environmental and social practices, promoting fair labor standards, and supporting sustainable sourcing practices.

For instance, Fashion Brand B has implemented a comprehensive sustainability program, which includes a strict code of conduct for its suppliers. This code ensures fair labor practices, prohibits child labor, and promotes sustainable material sourcing. By working closely with its suppliers, Fashion Brand B has achieved a 25% reduction in its overall environmental impact.

Risk Management and Resilience

Supply chains are vulnerable to various risks, including natural disasters, geopolitical events, and economic fluctuations. Effective risk management strategies are crucial for ensuring supply chain resilience and continuity.

Supply Chain Resilience Planning

Companies are now adopting comprehensive risk management frameworks to identify, assess, and mitigate potential supply chain risks. This involves developing contingency plans, diversifying supplier bases, and implementing robust inventory management strategies to minimize the impact of disruptions.

A successful example of supply chain resilience planning can be seen in the pharmaceutical industry. Pharmaceutical Company C has implemented a risk management strategy that includes diversifying its supplier network, maintaining strategic inventory reserves, and establishing alternative transportation routes. These measures have enabled Pharmaceutical Company C to maintain a stable supply of critical medications during global supply chain disruptions.

Blockchain for Transparency and Traceability

Blockchain technology is emerging as a powerful tool for enhancing supply chain transparency and traceability. By creating an immutable record of transactions and movements, blockchain can help companies track their products throughout the supply chain, ensuring product authenticity and traceability.

In the food industry, Food Producer D has adopted blockchain technology to enhance the traceability of its products. By integrating blockchain into its supply chain, Food Producer D can provide consumers with detailed information about the origin, processing, and transportation of their products, improving transparency and building trust.

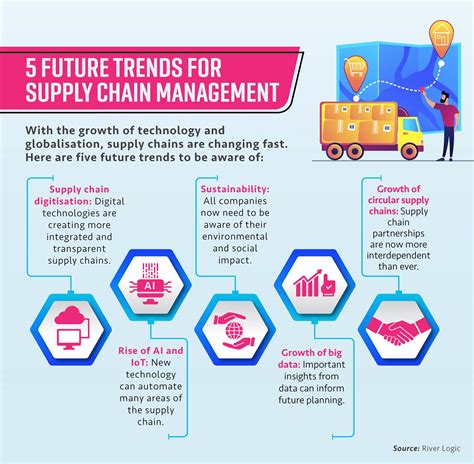

The Future of Supply Chain Practices

As we look towards the future, several key trends and innovations are set to shape the supply chain industry. These include the continued adoption of advanced technologies, such as AI, IoT, and blockchain, as well as the integration of sustainability practices into core business strategies.

Additionally, the rise of e-commerce and the growing demand for fast, flexible delivery options are driving the need for more agile and responsive supply chain networks. Companies will need to adapt their strategies to meet these evolving demands, ensuring they can deliver products efficiently and sustainably to meet customer expectations.

| Industry | Key Innovation |

|---|---|

| Automotive | Connected Supply Chain: Integrating AI and IoT for real-time data analytics and predictive maintenance. |

| Retail | Omnichannel Fulfillment: Leveraging technology to provide seamless shopping experiences across physical and digital channels. |

| Healthcare | Blockchain for Medication Traceability: Enhancing patient safety and supply chain integrity. |

| Manufacturing | Smart Factories: Implementing Industry 4.0 technologies for efficient production and real-time quality control. |

How can companies ensure ethical sourcing practices in their supply chains?

+Companies can ensure ethical sourcing by implementing comprehensive supplier evaluation processes. This includes conducting thorough due diligence, assessing suppliers’ social and environmental practices, and setting clear expectations and guidelines for responsible behavior. Regular audits and monitoring can also help maintain ethical standards throughout the supply chain.

What are some challenges companies face when adopting sustainable supply chain practices?

+Adopting sustainable practices can present challenges, including higher initial costs, resistance to change within the organization, and the need for specialized expertise. However, companies can overcome these challenges by setting clear sustainability goals, engaging stakeholders, and seeking partnerships or certifications that support their sustainability journey.

How can supply chain professionals stay updated with the latest industry trends and innovations?

+Staying informed about industry developments is crucial for supply chain professionals. They can achieve this by attending industry conferences and workshops, participating in professional networks and associations, and subscribing to reputable industry publications and websites. Additionally, staying connected with peers and industry influencers can provide valuable insights and knowledge sharing opportunities.