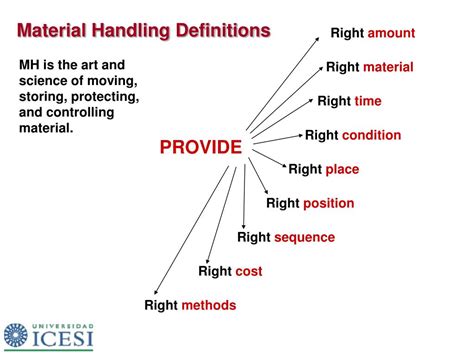

In the realm of logistics and supply chain management, the term "material handling" holds immense significance. It refers to the art and science of efficiently moving, storing, controlling, and protecting materials throughout the supply chain, from the point of origin to the point of consumption. In today's fast-paced and highly competitive business environment, optimizing material handling processes is crucial for ensuring smooth operations, reducing costs, and enhancing overall productivity.

Material handling is a multifaceted discipline that involves a wide range of activities and equipment. It encompasses everything from the initial receipt of raw materials to the final distribution of finished goods, covering various stages such as warehousing, packaging, transportation, and inventory management. By implementing effective material handling strategies, businesses can streamline their operations, minimize delays, and improve customer satisfaction.

The Scope of Material Handling

Material handling is a broad concept that covers a vast array of activities. It involves the planning, organization, and execution of various processes to ensure the smooth flow of goods and materials within a supply chain. Let’s delve deeper into the key aspects of material handling and explore its importance in modern business operations.

Key Components of Material Handling

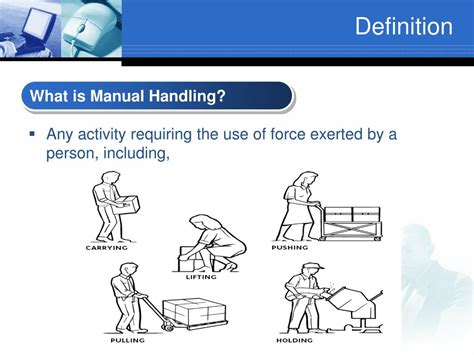

- Material Movement: This involves the physical transportation of goods from one location to another. It includes tasks such as loading, unloading, conveying, and transferring materials using various equipment like forklifts, conveyor belts, and cranes.

- Storage and Warehousing: Effective storage solutions are crucial for optimizing space utilization and ensuring the safe and secure storage of materials. Warehousing involves receiving, inspecting, and storing goods until they are ready for distribution.

- Inventory Management: Accurate inventory management is essential for maintaining optimal stock levels and ensuring the timely availability of goods. It involves tracking, monitoring, and controlling inventory to prevent overstocking or stockouts.

- Packaging and Protection: Proper packaging plays a vital role in protecting goods during transportation and storage. It involves selecting the right packaging materials and techniques to ensure the integrity and safety of products throughout the supply chain.

- Order Fulfillment: Material handling processes extend to order fulfillment, where accurate picking, packing, and shipping of goods are crucial for meeting customer demands and ensuring timely deliveries.

Benefits of Efficient Material Handling

Implementing efficient material handling practices offers a multitude of benefits to businesses. By optimizing material handling processes, companies can achieve significant improvements in various areas, including:

- Cost Reduction: Efficient material handling minimizes handling costs, reduces labor expenses, and optimizes space utilization, leading to significant cost savings for businesses.

- Improved Productivity: Streamlined material handling processes enhance overall productivity by reducing lead times, minimizing bottlenecks, and increasing operational efficiency.

- Enhanced Customer Satisfaction: Effective material handling ensures timely deliveries, accurate order fulfillment, and high-quality products, resulting in increased customer satisfaction and loyalty.

- Reduced Waste and Damage: Proper material handling techniques, such as using appropriate packaging and storage methods, minimize product damage and waste, improving overall product quality and reducing costs.

- Enhanced Safety: By implementing safety protocols and utilizing the right equipment, material handling practices can significantly reduce workplace accidents and injuries, creating a safer working environment.

| Industry | Material Handling Challenges |

|---|---|

| E-commerce | High volume of orders, fast-paced environment, accurate order picking and packing. |

| Manufacturing | Heavy and bulky materials, precise inventory management, efficient movement of raw materials and finished goods. |

| Retail | Frequent stock replenishment, space optimization, quick product retrieval for customers. |

Efficient Material Handling Solutions

To achieve optimal material handling efficiency, businesses must adopt innovative solutions and technologies. Here are some key strategies and tools that can revolutionize material handling processes:

Automation and Robotics

Automation and robotics have transformed the material handling landscape. By leveraging advanced technologies, businesses can enhance productivity, accuracy, and safety. Here’s how automation and robotics contribute to efficient material handling:

- Automated Guided Vehicles (AGVs): These self-guided vehicles navigate through warehouses and distribution centers, efficiently transporting materials from one location to another. AGVs improve productivity and reduce the risk of accidents compared to manual handling.

- Robotic Arms: Robotic arms are equipped with advanced sensors and vision systems, enabling them to handle delicate and precise tasks. They can pick, pack, and sort materials with high accuracy, reducing the need for manual labor.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS utilize advanced technologies to store and retrieve materials efficiently. These systems optimize space utilization, improve accuracy, and reduce the time required for material retrieval.

- Conveyor Systems: Conveyor belts powered by automation can transport materials smoothly and efficiently, reducing manual effort and increasing throughput.

Intelligent Software Solutions

Software solutions play a crucial role in optimizing material handling processes. Intelligent software platforms provide real-time visibility, accurate inventory management, and efficient order fulfillment. Here’s how software solutions enhance material handling:

- Warehouse Management Systems (WMS): WMS software streamlines warehouse operations by providing real-time inventory tracking, optimizing picking routes, and managing warehouse layouts. It improves overall warehouse efficiency and accuracy.

- Transportation Management Systems (TMS): TMS software optimizes transportation processes by selecting the most efficient routes, managing carrier relationships, and tracking shipments in real-time. It reduces transportation costs and improves delivery times.

- Inventory Management Software: Accurate inventory management is crucial for efficient material handling. Inventory management software provides real-time visibility into stock levels, helps prevent stockouts, and enables timely replenishment.

- Order Fulfillment Software: Order fulfillment software automates the process of picking, packing, and shipping orders. It improves accuracy, reduces errors, and enhances customer satisfaction by ensuring timely deliveries.

Ergonomic Equipment and Design

Ergonomics plays a vital role in material handling to ensure the safety and well-being of workers. By designing equipment and workspaces with ergonomic principles in mind, businesses can reduce the risk of injuries and improve overall productivity. Here’s how ergonomic considerations enhance material handling:

- Ergonomic Lift Equipment: Lifting heavy loads can be physically demanding and increase the risk of injuries. Ergonomic lift equipment, such as pallet jacks and scissor lifts, reduce the physical strain on workers, making material handling tasks safer and more efficient.

- Ergonomic Workstations: Designing workstations with ergonomic principles ensures that workers can perform their tasks comfortably and efficiently. Adjustable height tables, ergonomic chairs, and well-organized layouts contribute to a safer and more productive work environment.

- Training and Education: Providing comprehensive training on ergonomic practices and safe material handling techniques empowers workers to make informed decisions and adopt safe work habits. This reduces the risk of injuries and promotes a culture of safety.

The Future of Material Handling

The field of material handling is constantly evolving, driven by technological advancements and changing business needs. As we look towards the future, several trends and innovations are poised to shape the way materials are handled and managed.

Trends Shaping the Future

- Internet of Things (IoT): IoT devices and sensors are revolutionizing material handling by providing real-time data and insights. By connecting various components of the supply chain, businesses can optimize processes, track inventory, and improve overall efficiency.

- Artificial Intelligence (AI): AI-powered systems can analyze vast amounts of data and make intelligent decisions to optimize material handling processes. From predictive analytics to automated decision-making, AI enhances accuracy, productivity, and cost-effectiveness.

- Sustainable Practices: With a growing focus on sustainability, material handling practices are evolving to minimize environmental impact. This includes adopting eco-friendly packaging materials, optimizing transportation routes to reduce carbon emissions, and implementing energy-efficient equipment.

- Last-Mile Delivery Innovations: The last mile of the supply chain, where goods are delivered to the final destination, is becoming increasingly important. Innovations such as drone deliveries, electric vehicles, and autonomous trucks are transforming last-mile logistics, improving delivery times, and reducing costs.

- Collaborative Robotics: Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. Cobots can handle repetitive tasks, freeing up workers for more complex and value-added activities, thereby improving overall efficiency.

Conclusion

Material handling is a critical aspect of modern business operations, impacting supply chain efficiency, customer satisfaction, and overall productivity. By embracing innovative solutions, such as automation, robotics, and intelligent software, businesses can revolutionize their material handling processes and stay ahead in today’s competitive landscape. As we navigate the future, staying abreast of emerging trends and technologies will be key to optimizing material handling practices and driving business success.

What are the key challenges in material handling for e-commerce businesses?

+E-commerce businesses face unique challenges in material handling, such as managing high volumes of orders, ensuring accurate and fast order fulfillment, and optimizing warehouse space. These challenges require efficient picking and packing processes, accurate inventory management, and innovative solutions like automation and robotics.

How can businesses improve material handling efficiency in manufacturing industries?

+In manufacturing, material handling plays a critical role in streamlining production processes. To improve efficiency, businesses can invest in ergonomic equipment, implement lean manufacturing principles, and optimize material flow by minimizing bottlenecks and reducing unnecessary movements.

What are the benefits of using robotic arms in material handling processes?

+Robotic arms offer several advantages in material handling. They provide precise and accurate handling of materials, reducing the risk of errors and damage. Additionally, robotic arms can work continuously without fatigue, increasing productivity and reducing labor costs. They also enhance workplace safety by taking on repetitive and potentially hazardous tasks.