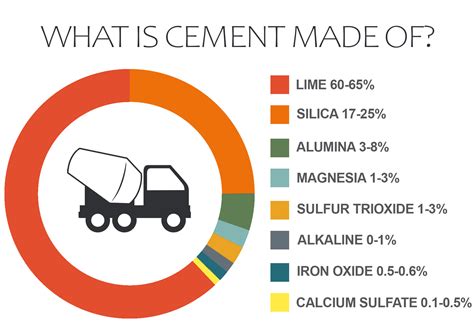

Cement is a fundamental component in the construction industry, serving as a binding agent that holds together aggregate particles such as sand, gravel, and crushed stone to form concrete. The composition of cement is complex and varies depending on the type of cement being produced. However, the primary components of cement include limestone, clay, sand, and other minerals such as iron ore and bauxite.

The process of manufacturing cement involves several stages, starting with the extraction of raw materials from quarries or open-pit mines. The raw materials are then crushed and ground into a fine powder, known as raw meal, which is fed into a rotary kiln. The rotary kiln is a large, cylindrical furnace that heats the raw meal to extremely high temperatures, typically around 1450°C, causing the materials to undergo a series of chemical reactions that ultimately produce a hard, glassy substance known as clinker.

The clinker is then cooled and ground into a fine powder, known as cement, which is the final product. The cement powder is highly reactive and will harden when mixed with water, making it an ideal binding agent for construction applications. The exact composition of cement can vary depending on the type of cement being produced, but it typically consists of a combination of the following compounds: tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF).

Key Points

- Cement is a binding agent that holds together aggregate particles to form concrete.

- The primary components of cement include limestone, clay, sand, and other minerals.

- The manufacturing process involves extracting raw materials, crushing and grinding them into a fine powder, and heating them in a rotary kiln to produce clinker.

- The clinker is then cooled and ground into a fine powder, known as cement.

- The exact composition of cement can vary depending on the type of cement being produced, but it typically consists of a combination of tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite.

Types of Cement

There are several types of cement, each with its own unique characteristics and applications. Some of the most common types of cement include:

Portland Cement

Portland cement is the most widely used type of cement and is suitable for a wide range of applications, including concrete, mortar, and plaster. It is made from a combination of limestone, clay, and other minerals, and is known for its high strength and durability.

Blended Cement

Blended cement is a type of cement that is made by blending Portland cement with other materials, such as fly ash or slag. It is often used in applications where a high level of sulfate resistance is required, such as in coastal areas or in areas with high levels of soil salinity.

Hydraulic Cement

Hydraulic cement is a type of cement that sets and hardens when exposed to water. It is often used in applications where a high level of strength and durability is required, such as in the construction of bridges and buildings.

| Type of Cement | Composition | Applications |

|---|---|---|

| Portland Cement | Limestone, clay, and other minerals | Concrete, mortar, and plaster |

| Blended Cement | Portland cement and other materials (such as fly ash or slag) | Coastal areas, high soil salinity areas |

| Hydraulic Cement | Limestone, clay, and other minerals | Bridges, buildings, and other high-strength applications |

Cement Manufacturing Process

The cement manufacturing process involves several stages, from raw material extraction to final product packaging. The process can be broadly divided into the following stages:

Raw Material Extraction

The first stage of the cement manufacturing process involves the extraction of raw materials from quarries or open-pit mines. The raw materials used in cement production include limestone, clay, sand, and other minerals.

Raw Material Preparation

The raw materials are then crushed and ground into a fine powder, known as raw meal, which is fed into a rotary kiln. The raw meal is typically a mixture of limestone, clay, and other minerals, and is designed to produce a specific chemical composition.

Clinker Production

The raw meal is then heated in a rotary kiln to produce clinker, which is a hard, glassy substance that is the primary component of cement. The clinker is then cooled and ground into a fine powder, known as cement.

Cement Grinding

The final stage of the cement manufacturing process involves grinding the clinker into a fine powder, known as cement. The cement is then packaged and shipped to customers for use in a wide range of applications.

The cement manufacturing process is complex and requires careful control of temperature, pressure, and chemical composition to produce high-quality cement. The process also requires significant amounts of energy and can have a substantial impact on the environment, making it essential to adopt sustainable practices and reduce emissions.

What is the main component of cement?

+The main component of cement is limestone, which is combined with other minerals such as clay, sand, and iron ore to produce a hard, glassy substance known as clinker.

What are the different types of cement?

+There are several types of cement, including Portland cement, blended cement, and hydraulic cement. Each type of cement has its own unique characteristics and applications.

What is the cement manufacturing process?

+The cement manufacturing process involves several stages, from raw material extraction to final product packaging. The process includes raw material preparation, clinker production, cement grinding, and packaging.