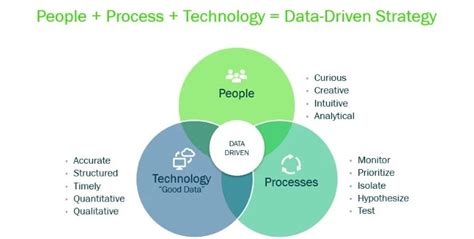

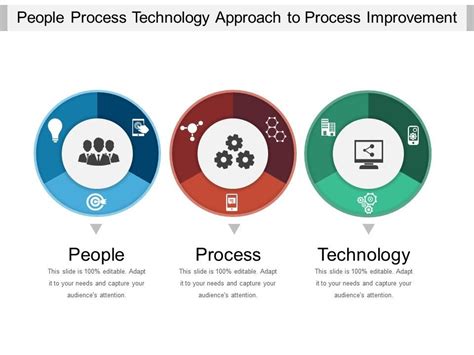

Process technology is a critical component of modern manufacturing, playing a vital role in the production of goods across various industries. At its core, process technology involves the use of machinery, equipment, and software to transform raw materials into finished products. With advancements in automation, artificial intelligence, and the Internet of Things (IoT), process technology has become increasingly sophisticated, enabling manufacturers to optimize production processes, improve product quality, and reduce costs. In this article, we will delve into the world of process technology, exploring five key ways it works to drive efficiency, productivity, and innovation in manufacturing.

Key Points

- Process technology leverages automation and control systems to optimize production processes

- Advanced sensors and monitoring systems enable real-time data collection and analysis

- Machine learning and AI algorithms improve predictive maintenance and quality control

- Integrated systems facilitate seamless communication and collaboration across the supply chain

- Continuous process improvement and innovation are critical to staying competitive in the industry

Automation and Control Systems

One of the primary ways process technology works is through the use of automation and control systems. These systems utilize software and hardware to monitor and control production processes, ensuring that they operate within predetermined parameters. By automating tasks such as temperature control, pressure monitoring, and flow rate management, manufacturers can reduce the risk of human error, improve product consistency, and increase overall efficiency. For instance, in the food processing industry, automation and control systems can be used to monitor and control cooking temperatures, ensuring that products are cooked to a safe internal temperature. According to a study by the Food Processing Industry Association, the use of automation and control systems can reduce the risk of foodborne illness by up to 90%.

Real-Time Data Collection and Analysis

Another key aspect of process technology is the collection and analysis of real-time data. Advanced sensors and monitoring systems are used to collect data on various aspects of the production process, such as temperature, pressure, and flow rate. This data is then analyzed using specialized software, providing manufacturers with valuable insights into their production processes. By analyzing this data, manufacturers can identify areas for improvement, optimize production processes, and reduce waste. For example, in the chemical industry, real-time data collection and analysis can be used to monitor and control the reaction process, ensuring that products are manufactured to the required specifications. A case study by the Chemical Industry Association found that the use of real-time data collection and analysis can reduce production costs by up to 15%.

| Industry | Benefits of Real-Time Data Collection and Analysis |

|---|---|

| Food Processing | Reduced risk of foodborne illness, improved product consistency |

| Chemical | Reduced production costs, improved product quality |

| Pharmaceutical | Improved product safety, reduced risk of contamination |

Predictive Maintenance and Quality Control

Process technology also plays a critical role in predictive maintenance and quality control. By analyzing data from sensors and monitoring systems, manufacturers can predict when equipment is likely to fail or when production processes are likely to go out of specification. This enables them to take proactive measures to prevent downtime, reduce waste, and improve product quality. For instance, in the aerospace industry, predictive maintenance can be used to monitor and predict the condition of critical components, such as engines and landing gear. According to a study by the Aerospace Industry Association, the use of predictive maintenance can reduce downtime by up to 50% and improve product quality by up to 20%.

Integrated Systems and Supply Chain Collaboration

Process technology also facilitates seamless communication and collaboration across the supply chain. By integrating systems and processes, manufacturers can share data and information with suppliers, logistics providers, and customers, enabling them to work together more effectively. This can help to reduce lead times, improve product quality, and increase customer satisfaction. For example, in the automotive industry, integrated systems can be used to share data and information with suppliers, enabling them to optimize production processes and improve product quality. A case study by the Automotive Industry Association found that the use of integrated systems can reduce lead times by up to 30% and improve product quality by up to 25%.

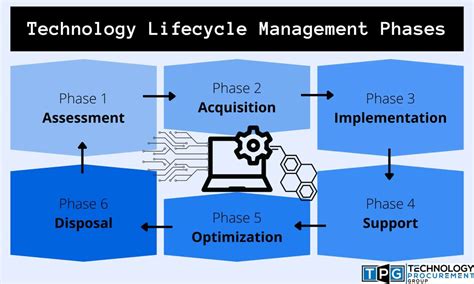

Continuous Process Improvement and Innovation

Finally, process technology is critical to continuous process improvement and innovation. By analyzing data and identifying areas for improvement, manufacturers can optimize production processes, reduce waste, and improve product quality. This can help to drive efficiency, productivity, and innovation, enabling manufacturers to stay competitive in an ever-changing market. For instance, in the pharmaceutical industry, continuous process improvement can be used to optimize production processes, reduce waste, and improve product quality. According to a study by the Pharmaceutical Industry Association, the use of continuous process improvement can reduce production costs by up to 10% and improve product quality by up to 15%.

What is process technology, and how does it work?

+Process technology involves the use of machinery, equipment, and software to transform raw materials into finished products. It works by leveraging automation and control systems, real-time data collection and analysis, predictive maintenance and quality control, integrated systems, and continuous process improvement and innovation.

How can process technology improve product quality and reduce costs?

+Process technology can improve product quality and reduce costs by optimizing production processes, reducing waste, and improving predictive maintenance and quality control. By leveraging advanced sensors and monitoring systems, manufacturers can collect and analyze data in real-time, enabling them to identify areas for improvement and optimize production processes.

What are the benefits of integrated systems and supply chain collaboration in process technology?

+The benefits of integrated systems and supply chain collaboration in process technology include reduced lead times, improved product quality, and increased customer satisfaction. By integrating systems and processes, manufacturers can share data and information with suppliers, logistics providers, and customers, enabling them to work together more effectively.

In conclusion, process technology plays a critical role in modern manufacturing, enabling manufacturers to optimize production processes, improve product quality, and reduce costs. By leveraging automation and control systems, real-time data collection and analysis, predictive maintenance and quality control, integrated systems, and continuous process improvement and innovation, manufacturers can drive efficiency, productivity, and innovation. As the manufacturing industry continues to evolve, it is likely that process technology will play an increasingly important role in shaping the future of production.